Power Take Off (PTO) is a crucial component in a wide range of machinery, particularly in agricultural, industrial, and transportation sectors. It serves as a mechanical connection between the engine of a vehicle or machine and external equipment, enabling power to be transferred and used effectively. Understanding how PTO works, its applications, and the benefits it provides can help operators make better decisions about equipment maintenance and usage, ultimately enhancing the efficiency and productivity of various operations.

What Is a Power Take Off?

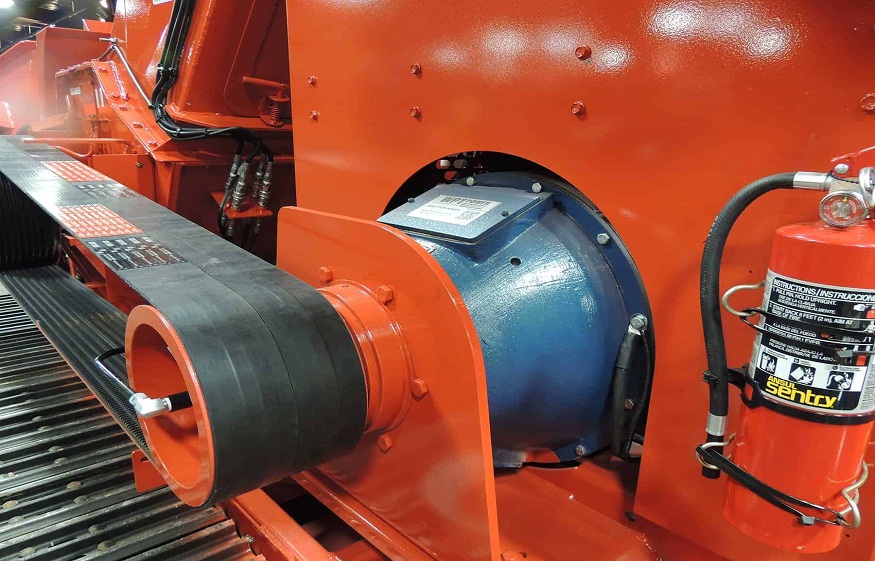

A Power Take Off is essentially a device that transfers mechanical power from an engine to external machinery or accessories. Most commonly found in vehicles and heavy machinery, PTOs are used to drive implements like hydraulic pumps, augers, winches, and generators. By utilizing the engine’s power, PTO systems enable a machine to perform multiple tasks simultaneously without the need for separate power sources.

PTOs are typically connected directly to the engine’s drivetrain and use the engine’s rotating power to drive external devices. For instance, in a tractor, a PTO might be connected to a mower, which allows the mower to operate using the tractor’s engine power. Without a PTO, each piece of equipment would require its own power source, which would make machines more cumbersome and costly to operate.

The mechanism of a PTO is simple yet highly effective. It typically consists of a rotating shaft that can be engaged or disengaged as needed. The engagement of the PTO shaft allows power to be transmitted, while disengagement stops the flow of power. This adaptability makes PTOs an essential feature in machinery that needs to perform multiple tasks without requiring a complex array of engines or motors.

Applications of Power Take Off

Power Take Off systems are versatile and can be found in a wide variety of industries, including agriculture, construction, and transportation. Their applications are vast, as they provide an efficient means of transferring power to a range of attachments and machinery. One of the most notable uses of PTO is in agricultural machinery, where it powers implements that help farmers with tasks such as tilling, mowing, and plowing.

In the agricultural sector, tractors are among the most common vehicles equipped with PTO systems. By connecting to a variety of implements such as seeders, harvesters, and sprayers, PTOs allow farmers to operate multiple tools simultaneously, saving both time and fuel. For instance, a PTO-driven irrigation system can pump water from a well, distributing it across a field without needing a separate engine to power the pump. This capability increases efficiency, reduces fuel consumption, and ensures that farmers can operate more equipment with less effort.

In construction, PTO systems are used to power a wide range of machinery, including concrete mixers, winches, and portable generators. For example, a PTO-driven concrete mixer can use the power from a truck’s engine to mix concrete on-site, eliminating the need for an additional motor or engine. This application is particularly beneficial in remote construction areas, where access to power sources may be limited.

Another industry that relies heavily on PTO systems is transportation. In trucks, PTOs are often used to power hydraulic systems that are responsible for operating equipment such as dump beds, hoists, and cranes. These systems can be engaged and disengaged as needed, making it easy for truck operators to load and unload heavy materials, often with the press of a button. This not only speeds up the process but also reduces the need for additional machinery, streamlining operations.

Advantages of Power Take Off Systems

The use of Power Take Off systems offers several significant advantages, which make them a preferred choice in many industries. One of the primary benefits is efficiency. PTOs allow one engine to power multiple pieces of equipment, reducing the need for multiple engines or motors and decreasing the overall fuel consumption of a machine. This leads to cost savings and makes operations more sustainable over time.

Another advantage of PTOs is their versatility. A single PTO system can power a variety of different implements, making it possible to adapt a vehicle or machine to a range of tasks without investing in separate equipment for each job. This makes PTO systems particularly useful for industries like agriculture, where a variety of tasks need to be completed using the same machine. For instance, a tractor with a PTO can be used for plowing, mowing, hauling, and even generating power for irrigation systems—all without the need for multiple machines.

PTOs also contribute to a more compact and organized setup. By utilizing a single engine to power multiple implements, there is no need for additional motors, which helps reduce the overall size of the equipment. This compactness is particularly beneficial for industries like construction and agriculture, where space and storage can be limited. Furthermore, PTO systems are often easier to maintain than separate engines, as they have fewer moving parts, making them more cost-effective in the long run.

Additionally, PTO systems are relatively simple to operate, which enhances safety and ease of use. Operators can engage and disengage the PTO system as needed, allowing for quick transitions between tasks. Most PTOs are equipped with safety features that prevent accidental engagement, reducing the risk of injury.

Key Considerations When Using Power Take Off

While Power Take Off systems offer numerous advantages, there are several important considerations to keep in mind to ensure safe and efficient operation. One of the most critical factors is the maintenance of the PTO system. Regular inspections are necessary to ensure that the PTO shaft and associated components are in good condition. Over time, the PTO shaft can become worn or damaged, which may lead to inefficiency or mechanical failure. Operators should also ensure that the PTO shaft is properly lubricated to prevent friction and overheating.

Another key consideration is the proper matching of the PTO to the machine or implement. It is important to ensure that the PTO’s power output is compatible with the requirements of the equipment being used. Mismatched PTO systems can cause undue strain on both the engine and the implement, leading to damage or failure. Proper training for operators is also essential, as misuse or improper handling of PTO systems can result in accidents or equipment damage.

Safety is always a top priority when working with Power Take Off systems. Since PTOs involve rotating shafts, they pose a potential risk of entanglement or injury if not used correctly. Operators should always ensure that the PTO is disengaged when not in use, and appropriate safety guards should be in place to prevent accidental contact with the rotating shaft. Additionally, operators should be trained to recognize the signs of PTO malfunctions, such as unusual vibrations or noises, which may indicate that the system requires maintenance.

Lastly, operators should be aware of the load limits of their PTO system. Overloading the system can lead to overheating, which can cause severe damage to both the PTO and the vehicle’s engine. It is important to follow manufacturer recommendations regarding load capacity and avoid excessive strain on the system.

The Importance of Power Take Off in Modern Machinery

Power Take Off systems have revolutionized the way machinery and equipment operate by enabling the efficient transfer of mechanical power from an engine to various external implements. These systems are integral to industries such as agriculture, construction, and transportation, where they provide the power needed to perform a wide range of tasks. The benefits of PTOs—efficiency, versatility, and reduced fuel consumption—make them an invaluable tool for operators seeking to optimize their equipment’s performance and reduce operational costs.

Whether used to power farm implements, construction machinery, or truck-mounted systems, Power Take Off systems continue to play a vital role in making modern machinery more efficient, safer, and more versatile. As technology evolves, PTO systems are likely to become even more efficient, offering new capabilities and opportunities for industries to increase productivity and reduce environmental impact.